Products

NSW type hand brake for freight train

Foot pedal type brake for railway freight train

Rubber parts for locomotive & rolling stock

NJUJ type colored liquid crystal display screen for locomotives

Continuous extrusion and cladding equipment kit

Fuel supply pump motor set with circular arc gear for locomotive

Rubber gangway diaphragm for passenger cars

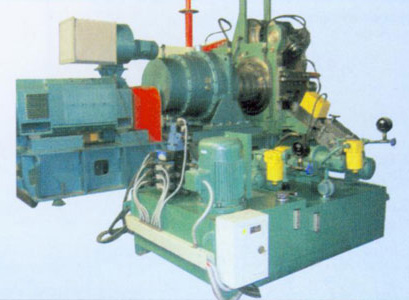

Continuous extrusion and cladding equipment kit

■ Product introduction

Continuous extrusion and cladding technique is the state-of the-art process for non- ferrous metal fabrication, cable production and metal-ware production. Compared with conventional processed, this technique features:

Continuous production without intervals,

Raw material is of same specification with cheap price

High material utilization and without sharp edges

Space, equipment and energy saving

Good finish of the product and accurate dimension

Cladding without seam with good seals

■ An introduction of production line with steel cladded by aluminum

The production line utilizes tangential continuous cladding technique to clad aluminum continuously on the outer surface of pretreated steel wire, and then employs double metal synchronous deformation technique to draw the wire to a specific dimension needed. The steel wire cladded by aluminum produced with this technique can come up to IEC standard and ASTM standard.

Technical specifications of the equipment typed LB350-2/200 is as follows:

| Nominal dimension of extrusion wheel | Rated rotation speed of main motor | Rated power of main motor | Cladding dimension with steel cladded by Al | Cladding speed |

| Ф340mm | 16.7 rpm | 200kw | Ф4-Ф8mm | 120m/min |

If equipped with some supplementary equipment, this production line can also produce a variety of shielded cables such as CATV and OPGW cables.

■ Flat ype copper wire continuous extrusion equipment kit

The production line consists of copper rod paying out machine, aligning machine, continuous extrusion machine, anti-oxide cooling system and wire rolling.

The production line features simple process, low investment, small production space, energy and labor saving, with the result of low cost. The quality of products are far superior to those made with traditional drawing process.

Characteristics:

Raw material is copper with same specification, easy stock preparation;

Continuous production with high production efficiency;

Extrusion process is the procedure of hot deformation so that tempering is not needed, with the result of remarkable energy-saving and good evenness.

Product modification can be obtained by replacing dies. It is especially suitable for small batches with diverse products.

Good machinability and microstructure can be achieved with good conductivity.

Smooth and stable surface;

Main parameters

| Type of extruder (300/120) | Section area | Average production | Average consumption of power | others | |||

| Nominal dimension of extrusion wheel | Rated power of main motor | Rated torque | Rated rotation speed | 15-150mm2 | 350 kg/h | 300 kW.h/ton | flash |

| 300mm | 120kW | 71000Nm | 12rpm | 3-5% | |||

| Workshop space requirement | Performance index of products | Tooling service life and estimated cost | ||||

| LXWXH | Operators | Conform to GB5584.1-85 standard | Extrusion wheel | Mould cavity | dies | estimated cost of tooling |

| 30X12X3 m | 2 persons per shift | 40-50 tons | 30-50 tons | 3-6 tons | Appx. 200 RMB/ ton | |

中文版

中文版